From Humble Spud to Smooth Spirit

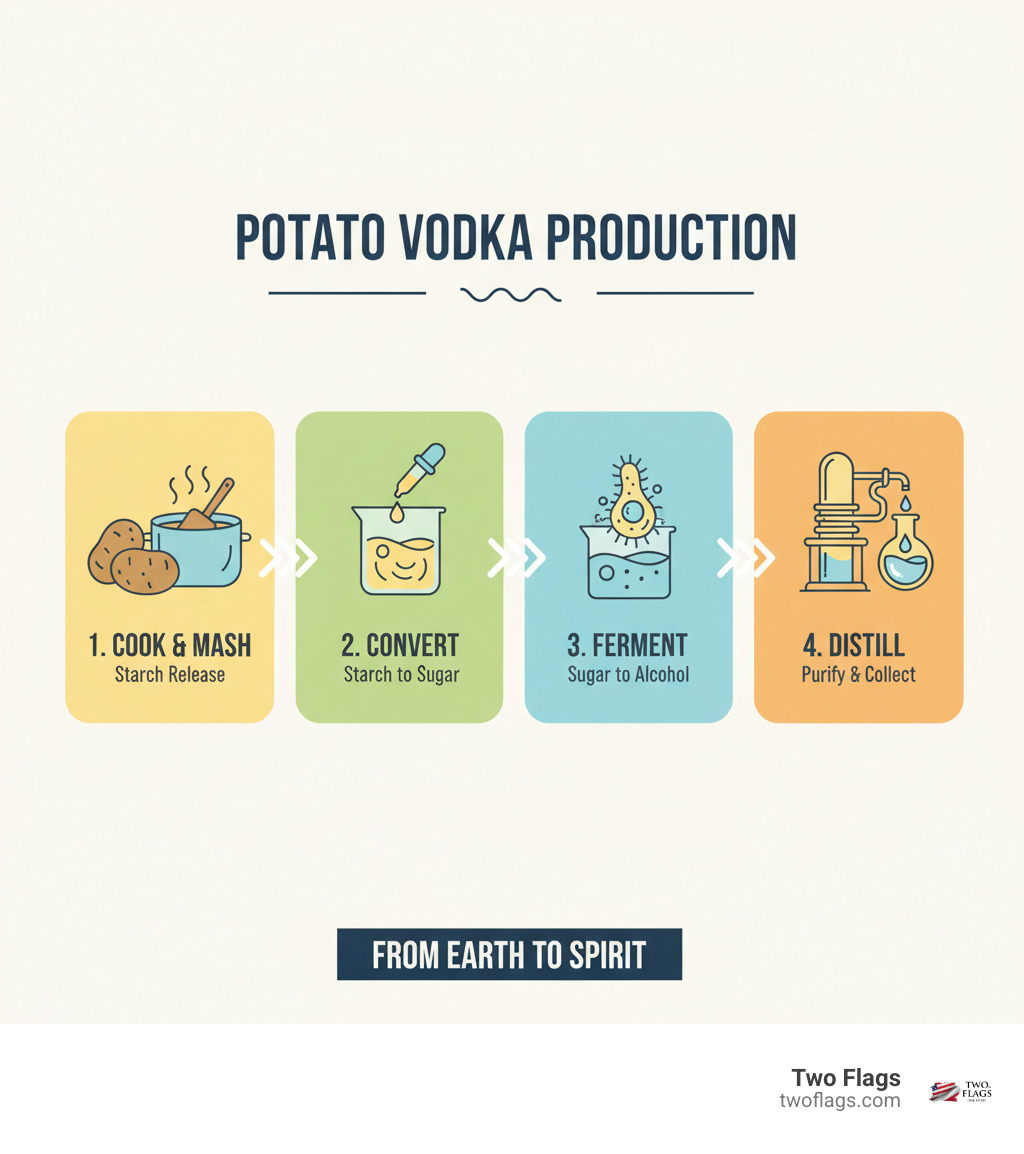

The journey of making vodka out of potatoes is a fascinating blend of tradition and science. It involves a few key steps to turn simple spuds into a smooth, potent spirit:

- Preparation: Potatoes are cleaned, cooked, and mashed to break down their starches.

- Conversion: Enzymes are used to turn these starches into fermentable sugars.

- Fermentation: Yeast is added to consume the sugars, producing alcohol.

- Distillation: The fermented liquid is heated, and the alcohol vapor is collected and condensed, purifying it into vodka.

Before we dive in, please note a crucial legal disclaimer: Home distillation of spirits for consumption is illegal in many jurisdictions, including the U.S. In others, like the U.K., it requires a license. This guide is for informational purposes only. Always consult your local laws and regulations before attempting any distillation.

I'm Sylwester Skóra, co-founder of Two Flags™ Vodka. My passion for craftsmanship is rooted in Polish heritage and American innovation. Join me as we explore the process of making vodka out of potatoes.

Relevant articles related to making vodka out of potatoes:

Before You Begin: Essential Equipment and Ingredients

Before you start making vodka out of potatoes, let's talk about what you'll need. Having everything ready makes the process flow smoothly.

Choosing the Right Potatoes

Not all potatoes are equal for distillation. The secret is starch content, which becomes alcohol. You want starchy potatoes with a floury texture like Russet or King Edward varieties. These high-starch potatoes maximize alcohol yield and contribute to the signature creamy finish of potato vodka. Potato vodka has a subtle, earthy character, much of which comes from the skins. I recommend scrubbing the potatoes and keeping the skins on to preserve these unique flavor compounds.

Essential Ingredients

Beyond potatoes, you'll need a few key ingredients:

- Malted barley contains natural enzymes that break down potato starch into fermentable sugars. Alternatively, you can use commercial amylase enzymes and glucoamylase for more precision.

- Distiller's yeast is a robust strain designed for vodka production that efficiently converts sugar to alcohol.

- Yeast nutrients ensure a vigorous, clean fermentation without off-flavors.

- Purified water is crucial, as tap water can contain minerals or chlorine that affect your vodka's final taste.

Necessary Equipment

The right tools make making vodka out of potatoes much easier:

- A large pot for boiling and mashing.

- A food-grade sanitizer is essential to prevent contamination that can ruin your batch.

- A fermentation vessel (a food-grade bucket or carboy) with an airlock to let CO2 escape while keeping contaminants out. Aim for a 30-liter vessel for a 25-liter wash to allow for foam.

- A hydrometer tracks the conversion of sugar to alcohol, and a thermometer is crucial for temperature control.

- The still is the heart of the operation. A pot still is simpler but may require multiple distillations. A reflux still (like a column still) is more complex but can achieve high purity in a single run, which is ideal for vodka.

- Several collection jars are needed for gathering the distillate and making cuts.

With everything gathered, you're ready to begin.

The Core Process of Making Vodka Out of Potatoes

This is where making vodka out of potatoes shifts from theory to practice. We'll break down starches, create fermentable sugars, and let yeast work its magic.

Step 1: Preparing the Potato Mash

First, wash and prepare your potatoes. Thoroughly scrub your starchy potatoes (like Russets or King Edwards), keeping the skins on for character. Chop them into 1-inch cubes to ensure they cook evenly.

Next, boil them for 15-20 minutes until fork-tender. This cooking process, called gelatinization, breaks down the potato's cell walls, making the starches accessible for conversion.

Once soft, it's mashing time. Mash them in the pot to create a smooth slurry, adding hot water as needed to achieve a more liquid consistency for the next step.

Step 2: Converting Starch to Sugar (Saccharification)

Yeast can't eat starch, so we must convert it to sugar. This critical process is called saccharification, and it requires precise temperature control.

If using malted barley, combine it with your mashed potatoes and water (about 7 gallons for 25 lbs of potatoes). Heat the mixture to 60 C (140 F), stirring constantly. Hold for 20 minutes, then raise the temperature to 67 C (153 F) and maintain it for one hour to allow the enzymes to break down the starches.

If using commercial enzymes, cool your mash below 65 C (149 F) and add alpha-amylase to liquefy the starch over 60 minutes. Then, stir in glucoamylase and let it work for another hour to complete the conversion to simple sugars.

An iodine test can confirm conversion: a drop of iodine on a cooled mash sample will stay yellowish-brown if successful, but turn blue-black if starch remains; see the iodine test for details. Finally, cool the mash quickly to 20-32 C (68-90 F) using a wort chiller or ice bath to prevent bacterial growth.

Step 3: Fermentation - Where Yeast Does the Work

Now, we'll turn our sugary wash into alcohol. Sanitize everything that will touch your wash: your fermentation vessel, airlock, spoon, and hydrometer.

Prepare a yeast starter by mixing your distiller's yeast with warm water (under 43 C/109 F) and a little sugar in a sanitized jar. After 20 minutes, it should be foamy and active.

Once your mash has cooled to the correct fermentation temperature (20-32 C or 68-90 F), pitch your yeast starter into the fermentation vessel. Ensure you've left adequate headspace for foam (e.g., a 30-liter vessel for a 25-liter wash).

Seal the vessel with an airlock and maintain a consistent ambient temperature. If a cap of solids forms, gently stir it down daily for the first few days. The bubbles in the airlock are escaping CO2, a sign of active fermentation. This typically takes 1 to 2 weeks.

When bubbling slows, use your hydrometer to check for completion. Take specific gravity readings over a couple of days. When the readings are stable and the wash tastes dry, fermentation is finished. Your potato wash is now ready for the still.

The Art of Distillation: From Wash to Pure Spirit

We're now at the most critical step in making vodka out of potatoes: distillation. This is where we separate and purify the alcohol. This process requires precision, patience, and an unwavering commitment to safety.

Safety First: A Critical Distillation Checklist

Working with alcohol vapors and heat is serious. These safety measures are absolute requirements.

- Ventilation is non-negotiable. Your distillation area must be extremely well-ventilated, as flammable alcohol vapors can accumulate.

- No open flames, sparks, or smoking should be anywhere near your still during operation.

- Check every connection and seal for leaks before applying heat. Leaks can release flammable vapors.

- The first portion of distillate (foreshots) contains toxic methanol and must be discarded. It can cause blindness or death if consumed.

Running the Still and Making the Cuts

With safety checks complete, transfer your fermented wash into the still, leaving sediment behind. Begin heating the still. Ethanol boils around 78°C (173°F), while water boils at 100°C (212°F). As you heat the wash, the alcohol vaporizes first, rises, condenses, and drips out as distillate.

Making the cuts is the art of separating the distillate into fractions. Collect it in small jars to evaluate each one by smell and taste.

- Foreshots: The first 100ml from a 25-liter wash. They smell like nail polish remover due to methanol and acetone. Discard them immediately.

- Heads: These follow the foreshots and have a pungent, solvent-like smell. They contribute to hangovers and should be kept out of your final product.

- Hearts: This is the pure, clean ethanol that will become your vodka. It smells neutral and clean. Collect this fraction until the smell begins to change. This typically comes off at temperatures between 90-95°C (194-203°F).

- Tails: The final fraction, containing heavier fusel oils that smell unpleasant (like wet dog or musty). Stop collecting for your vodka when you notice these off-notes or when the alcohol content drops below 30% ABV.

How Many Times Should You Distill for Purity?

The number of distillations depends on your equipment and standards.

- A pot still typically requires multiple distillations (two or three) to achieve the purity and smoothness needed for vodka. Each run removes more impurities.

- A reflux still is more efficient and can often achieve high purity in a single pass, making it ideal for neutral spirits like vodka.

There's a balance between purity and flavor. While vodka requires purity, excessive re-distilling can strip away subtle character. Triple distillation is a common standard for exceptional smoothness. The goal is to reach over 190 proof (95% ABV) before diluting it to drinking strength, ensuring a clean vodka that showcases the potato's character without harshness.

Finishing, Tasting, and Understanding Your Creation

After distillation, we arrive at the final stages: refining our spirit and appreciating the unique qualities of our homemade potato vodka.

The Final Steps: Dilution and Filtering

Your fresh distillate will be very strong—likely around 95% ABV (190 proof). It must be diluted to a drinkable strength.

Diluting to proof is the first step. Aim for the standard 40% ABV (80 proof). Use purified water to avoid introducing impurities. Add water slowly, measuring with your hydrometer until you hit the target.

Carbon filtering is the final polish. Running the diluted spirit through activated carbon removes lingering impurities and off-flavors, significantly improving smoothness and clarity. This can be repeated for an ultra-smooth finish.

The Unique Character of Potato Vodka

Only about 3% of vodka sold globally is made from potatoes, making it a special category. The taste profile of potato vodka sets it apart from grain-based versions. It has subtle earthy notes and a gentle sweetness reflecting its origins, especially if the skins were kept on during mashing.

Perhaps its most celebrated characteristic is the creamy mouthfeel. Potato vodka has a distinctive silky texture and viscosity that feels more luxurious on the palate, offering a smooth, velvety experience.

Common Challenges and Typical Yield in making vodka out of potatoes

Making vodka out of potatoes is rewarding but not highly efficient.

- Low yield is common. Commercially, it takes about 8.5 pounds of potatoes for one 750 ml bottle. Home production yields can be even lower, so a lot of work goes into a relatively small amount of product.

- Fermentation issues like "mash globbing" can make it difficult to extract all the sugars. Contamination is also a risk, which is why sanitation is so critical.

- Mashing difficulties can arise from poor temperature control, leading to incomplete starch conversion and a lower final yield.

Despite these challenges, the unique character of homemade potato vodka makes the journey worthwhile for any craft enthusiast.

Frequently Asked Questions about Making Vodka from Potatoes

We've covered a lot in our journey of making vodka out of potatoes. Here are answers to some common questions about this fascinating craft.

What is the historical origin of potato vodka?

The story of potato vodka begins in Eastern Europe, particularly Poland and Russia. While vodka has ancient origins, potatoes became a key ingredient in the 19th century because they were abundant and thrived in climates where grains struggled. Historically, vodka was also considered a medicinal spirit, used to treat ailments and disinfect wounds. This rich heritage speaks to the enduring tradition of potato-based spirits.

Is it legal to make potato vodka at home?

This is a crucial question. In the United States, it is generally illegal to distill spirits at home for consumption. While you can legally own a still for distilling water or essential oils, producing drinkable alcohol without a federal permit from the Alcohol and Tobacco Tax and Trade Bureau (TTB) is prohibited. Penalties for unlicensed distillation can be severe. In the United Kingdom, a license is required. Regulations vary significantly by country.

This guide is for informational purposes only. Always check your local, state, and federal laws before considering home distillation. Enjoying expertly crafted spirits from licensed distilleries is the safest and most legal option.

How is making vodka out of potatoes different from using grains?

While the principles are similar, the differences are significant. The primary difference is the starch source. Most vodka today is made from grains like wheat or rye; only about 3% uses potatoes. The mashing process also differs, as potato starch requires specific temperatures and handling to avoid a thick mash ("globbing").

The most important distinction is the final taste and mouthfeel. Grain vodkas are often crisp and peppery. Potato vodka, however, is renowned for its silky, smooth mouthfeel and creamy texture. It often has a slightly sweeter taste with subtle earthy undertones, feeling more viscous on the palate. This luxurious quality is why connoisseurs seek out premium potato vodkas.

Conclusion: The Spirit of the Spud

We've journeyed from farm to bottle, exploring every step of making vodka out of potatoes. This process, steeped in Polish and Russian tradition, shows how patience and precision can transform a humble root vegetable into a smooth, characterful spirit. Understanding the science of conversion, the art of fermentation, and the skill of distillation deepens our appreciation for the unique creamy mouthfeel and subtle earthiness of potato vodka.

Of course, making vodka out of potatoes at home is a significant undertaking. It requires specialized equipment, meticulous safety, time, and is subject to legal complexities. The yield can be modest for the effort involved, and achieving a perfect result takes practice.

For those who appreciate the rich tradition of Polish potato vodka but prefer an expertly crafted spirit, Two Flags One Spirit embodies that same dedication to quality. Our family-owned brand honors authentic Polish distilling traditions, delivering the luxury smoothness that defines exceptional vodka at an unbeatable value.

Whether you try home distilling (where legal and with proper permits) or leave it to the experts, understanding the journey from spud to spirit enriches the experience. To learn more about Poland's celebrated distilling heritage, explore The Spirit of Poland: Unveiling Traditional Vodka.

Zostaw komentarz

Ta strona jest chroniona przez hCaptcha i obowiązują na niej Polityka prywatności i Warunki korzystania z usługi serwisu hCaptcha.